The air diaphragm pump is one of the most adaptable bits of gear utilized in the food and drinks industry. They have diaphragms that work on compacted air to deal with liquids. There are two connected rooms with a diaphragm in each. An air spool control system that might get incorporated into the pump, is utilized to move the air starting with one gathering region and then onto the next.

This rehashed development of air starting with one get-together room and then onto the next can drive liquid out of one gathering room and into the ejection pipe, which then, at that point, gets loaded up with liquid in the additional gathering room. The Air Operated Diaphragm Pump has some release stream vibration that gets decreased by vibration dampeners in the release pipe.

Role of Diaphragm Pumps

The diaphragm pump is the super working gear for air-operated pumps, processing a wide range of liquids. These pumps are arranged as sure uprooting pumps as their fluid stream rates don’t differ fundamentally from the pump’s ejection.

They are used to carry liquids of all types, including those with high, low, and moderate viscosities, as well as mixtures containing a variety of particles. Diaphragm pumps can endure many unforgiving synthetic substances, including acids.

Read Also: 3 Major Differences Between Horizontal And Vertical Centrifugal Pumps

How does the Diaphragm Pump Work?

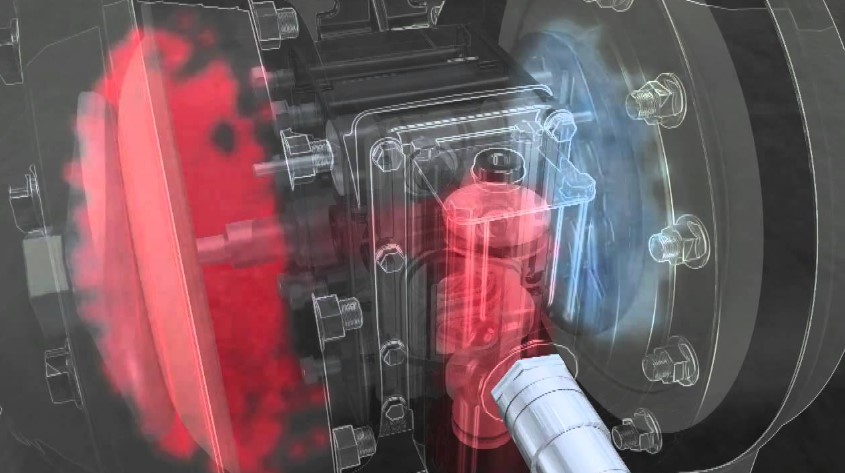

A diaphragm pump responds to and for to make an impermanent lobby through which fluid is gotten and shot out. The pump works on the idea of air relocation which goes about as an isolating divider between the air and the liquid.

The air diaphragm pump is a type of reliable dislodging pump that makes use of compressed air as a source of power. By means of a linked shaft, pressurized air is transferred from one chamber to the next. The opposite chamber is filled up with fluid while the main chamber is vacuumed out.

Benefits of Air Diaphragm Pump

Here are few Benefits of Air Diaphragm Pump below.

-

Numerous Options for Construction

AOD (Air-Operated Diaphragm) pumps have tracked down applications in numerous businesses, going from synthetic compounds, food handling, paints, gadgets, mining, and the middle between. Air-operated diaphragm pumps are available in a variety of sizes and materials. Their versatility allows them to work with practically any liquid. The material and estimate selection can be chosen to adapt to practically any liquid that should be pumped.

-

Oversimplified Design

The straightforwardness of AOD pumps makes them interesting to everybody from beginner to proficient clients. They are best depicted as a ‘plugin and play’ item because whenever they are associated with a compacted carrier, they deal with themselves; they can dry up dead-head without harm. Their usability joined with an exceptionally compelling capacity for pumping most materials pursues them the pump of decision for the overwhelming majority in the business.

-

Wellbeing

Since AOD pumps utilize compacted air as their main power source. They are characteristically protected and are accessible ATEX Certified for use in applications. Where it is unimaginable to expect to utilize power. It is risky to do such, like in dangerous or unstable conditions or at remote locales.

-

Adaptability and Discharge Capability

AOD Pump sizes from ¼” to 4″ are accessible giving stream rates somewhere in the range of 19lpm and 1,100lpm. Customers who want a pump with an adaptable size range can buy one from makers such as Oem Brand Pumps, which provides a wide range of adjustable sizes. To give a thought of what this implies in genuine terms, a ¼” pump will purge an IBC (1,000litres) of water in a short time while a 3″ pump will require only 1 moment.

One more fascination of AOD pumps comes from the way that standard units 1:1 proportion pumps, meaning the pneumatic force approaches the liquid tension out giving potential release tensions of up to 8bar. This without referencing the high tension for example 2:1 proportion pumps.

-

Thick Fluids

Air-operated diaphragm pumps can deal with various liquid viscosities. Having a pump that can ship both high and low thick materials implies. A pump can be utilized for various undertakings. Some other pump types can’t deal with exceptionally gooey liquids and will quit working or break down under similar circumstances.

-

Grating Materials

Just with taking care of low and high viscosities, AOD pumps can likewise handle destructive or rough liquids, as well as additional strong or powdered materials.

-

Delicate pumping

These diaphragm pumps have no impellers or other moving parts presented to the fluid being pumped. That implies that they are appropriate for shipping shear delicate media.

-

Dry up

AOD pumps can dry up without harming the pump or bringing about any issues. Some other pump types will continuously have to remain prepared and not dry up or they will either harm the entire pump or a portion of the parts, coming about in an expensive modification.