Producing cars has always been a balancing act. Manufacturers want to simplify processes while dealing with increasing complexity. Electric vehicles are pushing innovation even further, leaving companies battling rising costs and complicated production methods. In this race, finding ways to save time, reduce effort, and cut expenses is key—but it’s a tough nut to crack.

That is where gigacasting comes in. This modern production process redefines the production of key car components, reduces production time and costs, and delivers efficiency and sustainability benefits. It is already transforming businesses such as Tesla and Volvo. But is it the right move for every automaker?

Keep reading to see the opportunities and challenges behind Gigacasting—and how it could affect the future of car manufacturing. Let’s begin!

What is Gigacasting?

At its core, the idea is deceptively simple. For decades, a car’s frame (the “chasis”) has been built by stamping hundreds of individual metal parts and then welding or riveting them together. It’s a complex, time-consuming, and labor-intensive process.

Gigacasting, or megacasting, flips that script.

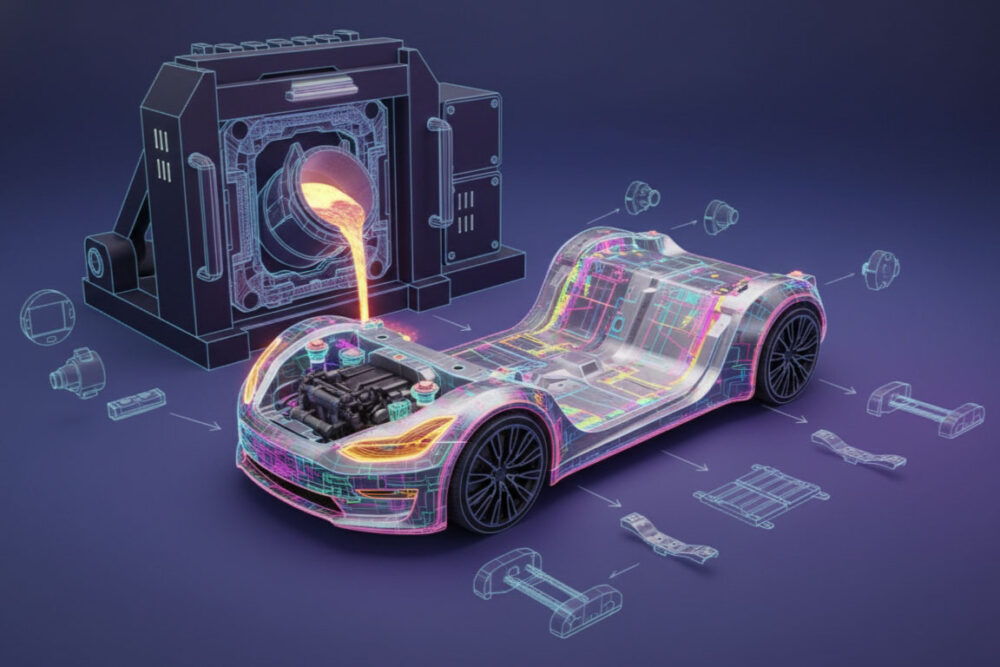

Instead of assembling 50 to 100 individual parts, manufacturers use an enormous machine to create a single, massive component. This process uses high-pressure die casting (HPDC), in which molten aluminum is injected at high pressure into a mold, or “die,” to form a large, intricate part, such as the entire rear or front end of the car.

“Gigacasting” is simply the term Tesla’s marketing department coined for it, but it’s the same technology.

A Bit of Historical Context

High-pressure die casting itself isn’t new. It has long been used by automakers to make smaller aluminum parts such as engine block and structural parts.

The real revolution is the sheer scale. Tesla manufacturing deserves the credit for popularizing the concept and pushing it to unprecedented sizes. The difference is staggering: Tesla’s Model 3 has a rear structure made from 171 separate metal pieces. By using gigacasting, the Model Y achieves the same structural integrity with just two megacast components, eliminating an estimated 1,600 welds in the process.

Also Read: Extended-Range Electric Vehicles Drive Growth

The Gigacasting Process

So, how does this work? First, you need a Giga Press. These are not your average factory machines; they are the size of a small building.

Supplied by companies such as Italy’s IDRA and Switzerland’s Bühler Group, these giants weigh thousands of tons and can exert clamping forces of 6,000 to 12,000 tonnes.

The process is highly complex:

- Molten aluminum is injected into the massive steel mold.

- The machine holds the mold shut with immense pressure as the part cools and solidifies.

- The giant, single piece is extracted, trimmed, and inspected.

Because the parts are so large and the investment is so high, manufacturers can’t afford “trial and error.” They rely heavily on advanced simulation software to perfect every detail—from how the metal flows to how it cools—before ever building the physical mold.

Benefits of Gigacasting

This is why carmakers are lining up to spend tens of millions on these machines. The benefits are transformative.

A. Radical Simplicity and Cost: The main business case is “production minimalism”. By replacing 100 parts with one, you eliminate 99 supply chains, 99 assembly steps, and all the robots, factory space, and labor that go with them. Tesla claims this slashed 40% off the manufacturing cost of their Model Y frame.

B. Speed: The time it takes to turn raw aluminum into a finished chassis part drops from months (for tooling and stamping) to days.

C. Manufacturing Consistency: When you assemble 100 parts, tiny errors in each one can add up, a problem known as cumulative tolerances. Gigacasting delivers dimensional accuracy within tight tolerances directly from the mold, leading to a better and more consistent final build.

D. Strength and Weight: A single piece of metal has no weld joints, which are traditional weak points. This “structural continuity” gives the whole car frame a firmer and safer look. It’s also much lighter. Volvo is aiming to achieve a 15-20 percent portion weight loss of the rear chassis of its next all-electric EX60.

Gigacasting and Electric Vehicles

This technology and EV production are a perfect match.

That weight savings is “critical” for EVs, because every kilogram you save positively influences…range.

The large, flat, rigid structures are also perfectly suited for building the “skateboard” chassis common to all EVs. They create a strong, protective “central battery-and-cabin unit”. This explains why EV-native firms, such as Tesla, NIO, and XPeng, and established giants that are transitioning to EVs, such as Volvo, Ford, and Toyota, are embracing the technology.

Also Read: The Future of EVs: ADAS Service Revolution in a Nutshell

Environmental Impact

This is a complicated one. The key component, aluminum, is very energy-intensive to create and carries with it a heavy carbon footprint. In fact, about 80% of the part’s CO2e (carbon footprint) comes from the aluminum itself.

However, the manufacturing process is much greener.

- Traditional stamping can waste up to 50% of each metal blank.

- Gigacasting, with in-house recycling of all scrap, can achieve 95% material utilization.

The total energy needed to melt and cast one giant part is also “significantly lower” than the combined energy of stamping, moving, and welding 100 individual parts.

The solution? Companies like Volvo are committing to source low-carbon aluminium. They claim this move makes their gigacast part less carbon-intensive than a traditional welded steel floor.

Challenges and Limitations

If gigacasting is so revolutionary, why isn’t every single automaker using it? Because it’s incredibly hard and comes with serious risks.

A. Astronomical Cost: The initial investment is the biggest roadblock. A Giga Press alone costs $18-25 million, and then you have to add the cost of the mold. A single megacasting mold can exceed £12 million, while traditional stamping dies might cost $1.2-2.5 million.

B. It’s a Volume Game: Because of the high cost, this process only makes economic sense at massive production volumes. The estimated breakeven point is over 100,000 cars per year for a single die.

C. Inflexibility: That £12 million mold is for one part, exactly as designed. Making a minor update to refresh your cycle will often require an entirely new tool, which is highly expensive.

D. Repairability: This is the big concern for customers and insurers. If you get in a fender bender, can a body shop repair it? Or does a small amount of damage to a giant, integral part mean the entire car is a total write-off? The solution is to design sacrificial crash-absorption systems around the megacasting, so the casting itself is only damaged in a very severe accident.

MORE ON AUTOMOTIVE INNOVATION

Chip Crisis 2025: Auto Industry Faces Shortage Scare Again

The Service Drive: Where the Giga-Problem Lands

Gigacasting doesn’t eliminate complexity. It transfers it.

It moves complexity from the (OEM-controlled) factory floor and pushes it directly onto the (dealer-controlled) service drive.

This new, high-stakes repair environment demands an elite-level “Master Technician” to diagnose and handle these repairs. But the industry is already facing a massive technician shortage, struggling to find, train, and keep good talent.

The only way to solve this is to stop finding talent and start building it. You must have a really good system to turn entry-level employees into the master techs you will desperately need.

But training is useless if those techs leave. In this new Giga-Problem world, tech frustration will skyrocket—not over pay, but over poor systems, weak service advisors who can’t sell the complex repair, and a lack of support. Before you do anything else, you must understand the real factors behind it.

This entire ecosystem of challenges—training, retention, systems, processes, and profitability—lives in one place: Fixed Operations.

As dealership sales fluctuate, Fixed Ops and the Service Drive remain the consistent, profitable heart of the business. Cars will ALWAYS need to be fixed. But how they are fixed is about to get a lot more complicated.

Ready to Optimize Your Fixed Ops Revenue?

Considering the benefits of fixed operations, not only in the form of a constant income, but also in the form of increased customer loyalty, it is apparent why numerous dealerships are looking into the field to diversify their sources of revenue. Chris Collins Inc. specializes in helping dealerships optimize their fixed operations, providing signature coaching on how to streamline processes, train staff, and deliver exceptional service.

Working with Chris Collins Inc. will let you turn that “Giga-Problem” into your greatest competitive advantage and drive long-term success.

📞 Book Your 15-Minute Opportunity Analysis Call with Us Today!

Future Outlook

Despite the challenges, the tide seems to be turning. The revolution is spreading.

Tesla, Volvo, Ford (with its “unicasting” approach), Toyota, Nissan, and Hyundai are all using or planning to use megacasting. Chinese EV manufacturers like NIO and XPeng are also aggressive adopters.

The technology is also evolving. Tesla is already working on a way to die-cast almost the entire vehicle underbody in one single piece. And the machines are getting even bigger. Suppliers are now studying 20,000-tonne presses to create full battery trays and other massive structures.

Conclusion

To wrap up, gigacasting represents more than just a new manufacturing process. It’s a fundamental shift in how we build things. While its ultimate dominance isn’t guaranteed, it has permanently changed the conversation and forced the entire industry to rethink a century of manufacturing tradition. If you found this helpful, share it with someone curious about innovation in manufacturing. Let’s keep the conversation going!

—

Author: Maverick Steel is a writer and digital marketer who enjoys connecting the dots for strategy and engaging content. He spent 6 years in secondary education as a proud campus journalist, specializing in editorial and column writing. Holding a bachelor’s degree in Marketing Management, Maverick is also a devoted advocate for positive cyber citizenship and a certified pet lover. When he’s not busy writing, you can catch him hitting the gym or enjoying a matcha latte at the nearest aesthetic coffee shop.